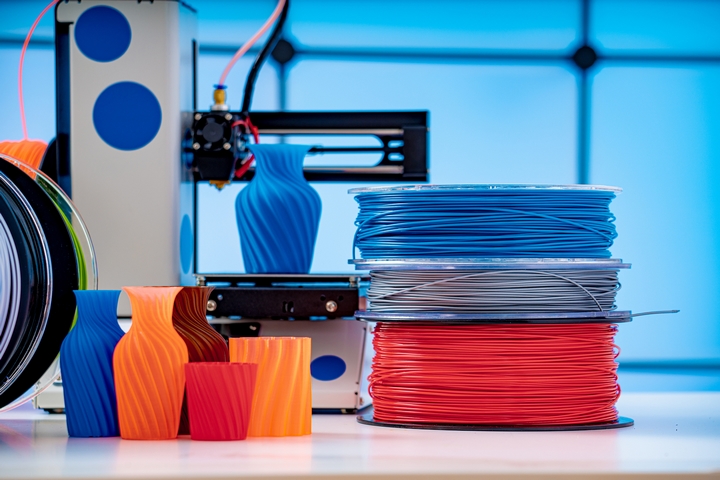

Over the years, the 3D printing industry has been growing like crazy. With all sorts of new innovations being made, machines now exist to print everything from plastics, metals, composites and more. Each 3D printing material has its own set of unique features and can offer various strengths of weaknesses depending on the job you’re hoping to accomplish.

In addition to accounting for concerns like texture and cost, choosing the right material for your 3D printing job will play a big role in the overall success. Here are the top ten materials used in 3D printing and how to choose a one that is right for you.

1. Nylon

Also known as polyamide, nylon is a synthetic thermoplastic linear polyamide and is the most common plastic material. A popular choice for 3D printing thanks to its flexibility, durability, low friction and corrosion resistance, nylon is also suitable to use when creating complex and delicate geometries. Inexpensive and easily dyed or coloured, it is important to remember that hydroscopic and should therefore be kept dry.

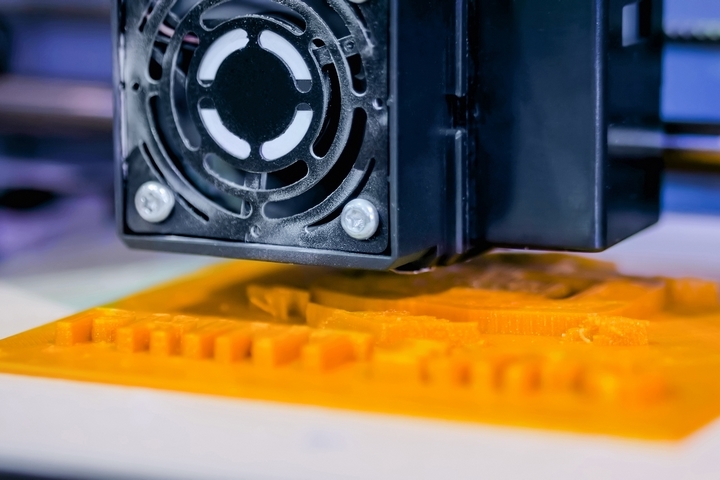

2. ABS

ABS (Acrylonitrile Butadiene Styrene) is a thermoplastic and another material very commonly used as a 3D printer filament. The go-to choice for many 3D printing jobs, ABS is super accessible, affordable, and available in a wide variety of colours. It has a longer lifespan than nylon and is quite mechanically strong.

Even though for those concerned with their carbon footprint, it is worth noting that ABS is essentially a non-biodegradable toxic material, and that it releases toxic fumes and produces an awful smell at high temperatures.

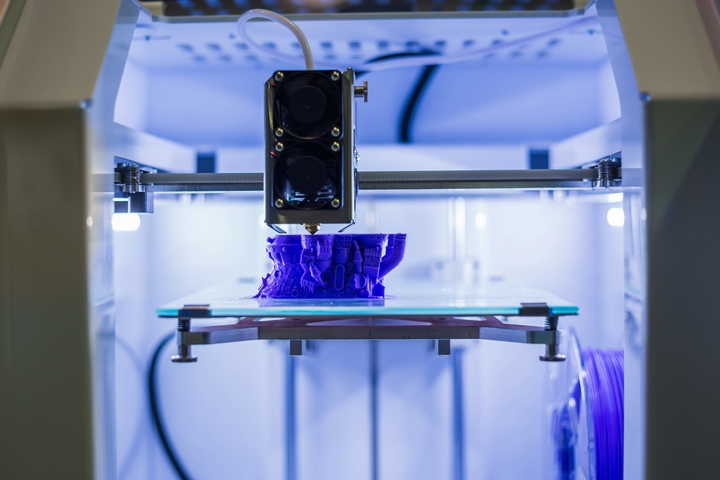

3. Resin

Used in SLA, DLP, Multijet or CLIP technologies, resin is another popular choice for 3D printers. There are various types of resins that can be used in 3D printing, including castable resins, tough resins, and flexible resins. Available for many different applications, it has low shrinkage and high chemical resistance. A few of the drawbacks include the fact that it needs to be stored securely due to its high photo-reactivity and the fact that it is expensive.

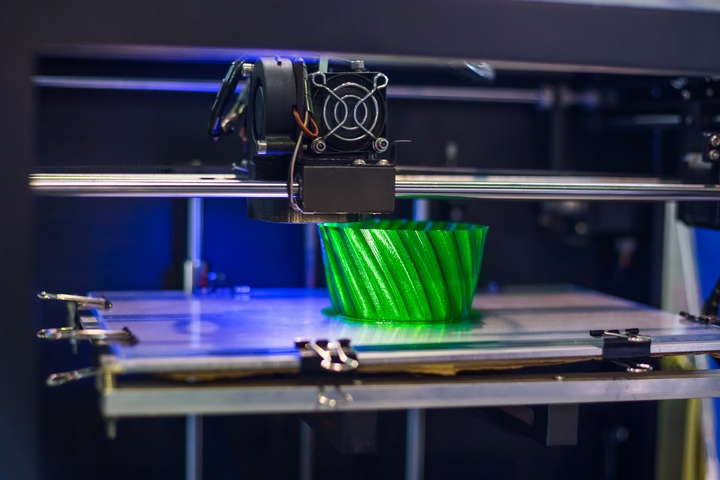

4. PLA (Polylactic Acid)

A much greener choice within the world of 3D printing materials, PLA or Polylactic Acid are made from renewable resources such as sugarcane or cornstarch. Mostly used in primary and secondary schools since it is safe to use and easy to print with, PLA can print with sharper corners and features compared to ABS material and is available in many different colours.

5. Gold and silver

While these are rather unconventional materials used in 3D printing, it is possible to 3D print using gold and silver. These sturdy materials are processed in powder form and generally used in the jewellery sector. Heat proof with high electrical conductance, as you might have guessed, printing with gold and silver is also expensive.

6. Stainless steel

Used for printing by fusion or laser sintering, printing with stainless steel is all about strength and detail. Perfect to use for miniatures, bolts and key chains, stainless steel provides strong resistance against corrosion and has high ductility. That being said, it has a long building time and printing size is limited.

7. Titanium

The strongest and lightest material for 3D printing, titanium is used in the process called Direct Metal Laser Sintering. Used primarily in high-tech fields such as space exploration, aeronautics and medical field, it provides greater complexity and resolution in design. Although on the pricier side of things, it is biocompatible and resists corrosion.

8. Ceramics

These are one of the newer materials used in 3D printing. Ceramics are more durable than metal and plastic and can withstand extreme heat and pressure without even breaking or warping it. It can produce high-precision components with a smooth and glossy surface and is also available in a wide range of colours. That being said, since it is fragile, ceramics has limitations in printing objects with enclosed and interlocking parts.

9. PET/PETG

PET or Polyethylene terephthalate is another frequently used plastic. Used in thermoforming processes, it can also be combined with other materials like glass fiber to create engineering resins. Durable, impact-resistant and recyclable, PETG can be sterilised and has an excellent layer adhesion. On the downside, PETG can be weakened by UV light and is also prone to scratching.

10. HIPS

HIPS or High Impact Polystyrene, these are referring to plastic filaments that are used for support structures in FDM printers. More or less comparable to ABS when it comes to ease of use, HIPS is completely soluble to a liquid hydrocarbon called limonene.

Overall, it offers the benefit of having good machinability, which allows it to make complex structures while remaining smooth and lightweight. Fairly inexpensive, it is also water resistant and impact resistant. Disadvantages include the fact that it needs to be used only in a ventilated area due to strong fumes and that it requires a pretty much constant heat flow. Without that, this material can clog up nozzle and delivery tubes of the printer.